Rural E-beam Furnaces

One of the more interesting element road trips I've been on was with Oliver Sacks and our mutual friend Nick to an e-beam furnace in rural New Jersey on August 6th, 2004. We were on a mission to melt Sacks' kilogram of iridium down into a solid ingot, which is a lot harder to do than you might think at first. My friend Max Whitby sold him the iridium originally in the form of marble-sized lumps, the best that can be done with a mere reduced pressure argon-arc furnace. To make a solid ingot that big you need a much more powerful vacuum furnace that heats the metal with an electron beam. So off to New Jersey we went.

Kaistar R&D is a high-tech company employing sophisticated, custom designed electron beam technology to make unique products. Like all such facilities I've visited, it's in an idyllic rural setting with horses. (OK, I've only visited one other electron beam facility, a 5MeV accelerator in Ohio's Amish country, but still it seems like a pattern. I don't know what the horses think of it.)

Sacks, an amateur botanist as well as an amateur element nut, had a fine time exploring the grounds before we got down to business:

Here he is looking at some horsetail, an ancient plant giant versions of which make up the bulk of the coal we burn today (or so says Sacks):

The magnetic levitation e-beam furnace (which suspends the metal being molten by high-frequency electromagnetic levitation) was in crates awaiting shipment to their new factory at an undisclosed location in Central Europe, so we had to use the other one, a rather imposing 100 kilowatt copper-hearth unit:

It's big, but in a down-home sort of way, and most of it is concerned with creating a very good vacuum in the melting chamber, comparable to a deep space vacuum. It's fun looking at a picture of one of these things and trying to decode what each of the parts does. At first it seems like a tangled mess of wires and hoses, but slowly different sections start to make sense.

The green vertical things with spiral tubing around them are twin diffusion pumps. They are connected on the left to a pair of roughing pumps. (Diffusion pumps don't start to work until you already have what I would consider a pretty damn good vacuum: They take it the rest of the way down.) You can tell that vacuum is important to this machine because those are very big twin diffusion pumps, and if you look closely you'll see there are even a couple more smaller ones (orange) near the top of the machine.

You can follow the vacuum by looking for big tubes: At very high vacuum air moves slowly and large diameters are needed to keep the few molecules left moving towards the pumps. There appear to be motorized gate valves allowing the pumps to be connected to different parts of the system: This tells me they cycle it up and down a lot and need to be able to isolate the diffusion pumps to avoid contaminating them with too much air.

The orange cylinder pointing down from the very top is the start of the electron gun. (I figured that much out myself but Philip Kapchenko told me I was only half right: That part is actually just a cooling chamber, the real gun starts just below it). Basically this is the same thing as the back of a TV picture tube only bigger and with water cooling. Electrons are accelerated from the cathode (a tungsten button) through a high voltage electric field (similar voltage to that of a large TV tube), until they strike the target, in this case a lump of metal to be melted instead of phosphors on a screen. Along the way the beam is steered and focused by magnetic lenses, again just like in a TV picture tube.

The only real difference is the amount of current in the electron beam: A milliamp or so in the case of a TV tube, ten thousand times as much in this furnace.

The large horizontal tan-colored cylinder underneath the electron gun is the business end of the machine: The melting chamber. I have no photos of the inside of the chamber: It's secret. Or of the control panel, that's secret too. In fact, quite a bit of the operational parameters of this machine are secret.

The company uses it to serve the research and development community with ultra-high purity metals and complex, multi-part alloys that are difficult or impossible to make by other means. Our enthusiastic guide, Philip Kapchenko, uses it to produce ultra-pure element samples to sell on eBay and on their website (click the "Krdnet Supplies" button to see their offerings for the element hobby).

This is a rare and refreshing example of a sophisticated, high-tech company that is actually set up to deal with lowly element collectors such as myself. Usually at a company like this the first six people you talk to say there's really nothing they can do: It's not until you find the guy in the back room who actually runs the place that you find someone who understands why you might want just a small button of what they make.

Anyway, back to our visit. After saying goodbye to his iridium buttons, which he had grown quite fond of, Sacks handed them over to Philip for loading into the secret furnace chamber. While photographs of the chamber and crucible were strictly off limits, photographs of the actual melting process underway were OK, since it's impossible to make out anything of the internals of the furnace. Here is a sequence showing how the buttons are heated and then coalesced into a puddle:

Here is a

video clip of the process.

You may notice some flickering in the movie: That's because this object, which appears quite normal in these pictures, is actually astronomically bright and can be viewed or photographed only through a rotating metal shutter with a thin slit in it. Iridium doesn't melt until it reaches more than 2400C, roughly the temperature of a light bulb filament. Imagine a couple of square inches of solid metal every bit of which is glowing as brightly as the filament in an ordinary light bulb: Several tens of kilowatts of power is leaving the metal in these pictures in the form of light. Welder's glass would shatter or melt trying to absorb that much energy. Worse, the metal is actually evaporating at a good clip while it's melted (not so much with iridium, but metals like titanium are quite volatile when molten). A fixed sheet of glass would be covered by a millimeter or more of titanium after a melting cycling, simply from condensation of titanium vapor. Needless to say a millimeter of titanium is a bit hard to see through, hence the spinning shutter, which presumably just needs to be scraped off from time to time.

The extreme brightness also explains why it's so hard to work with these high-melting metals. Radiant heat loss is so fierce that the metal will not stay molten for more than a second after removing the heat source (in this case an electron beam). Casting in the ordinary sense is completely impossible: The stream would freeze long before it hit the mold, so if you want to fill a certain shape you have to melt it directly in the mold.

After melting from both sides and a lengthy cool down period (plus a couple of "ouch, where are my gloves" moments) Sacks' iridium was consolidated into a block a little over 2" square and less than 1/2" thick, weighing 1.7 pounds. It's startlingly heavy, distinctly more so than a similar sized tungsten block (which would be about 15% lighter and about 10,000% cheaper). The full melting process ensures that it is very near its theoretical density of 22.6g/cc, unlike common sintered or partially molten samples that may be only 95% of theoretical density.

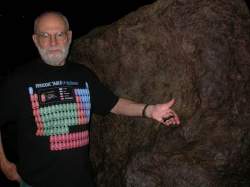

After we got back to New York we decided to pay a visit to another notable lump of iridium, the 34-ton iron meteorite named Ahnighito at the Natural History Museum. Why do I say it's a notable lump of iridium if it's made of iron? Because iron meteorites are unusually high in iridium. In fact the first evidence for a massive meteorite being responsible for the extinction of the dinosaurs was the discovery of an iridium-rich layer at just about the right point in the fossil record.) Here is Sacks holding his iridium up next to Ahnighito, which for comparison contains only about 0.34 pounds of iridium, according to calculations kindly supplied by Joseph Boesenberg, the curator of meteorites:

Ahnighito was part of a larger meteorite, of which a total of 58 tons have actually been found: More may be under the ocean, and the Eskimos of the northwest coast of Greenland had been using the iron for generations as well, reducing the size of the parts that were found. To match Sacks' 1.7 pound lump the original meteorite would have had to weight 170 tons, which it well might have though no one really knows. (Handy rule of thumb if you're thinking of getting into asteroid mining: A typical iron meteorite of this class has about 1/100 of a pound of iridium per ton of iron.)

|

|